Estimating

Create manufacturing estimates for new items. Control costs and markup for fixed and variable cost elements. Integrate estimating with quotes with embedded CRM.

Key business benefits

Related Resources

Begin Every Manufacturing Process with a Fast, Accurate Estimate

Job shops and make-to-order manufacturers define new finished goods by creating a manufacturing estimate based on customer specifications or customer-supplied engineering drawings. Optional PLM and CAD connectors streamline estimate creation by harmonizing engineering bills of material from connected product design application into Acumatica for new part estimates.

Manufacturing estimates can be created from scratch or copied from previous estimates, existing bills of material and routings, or previous production orders. Initiate estimates from the CRM opportunities screen or the manufacturing application. CRM integration empowers companies to manage the complete sales process for custom manufactured products.

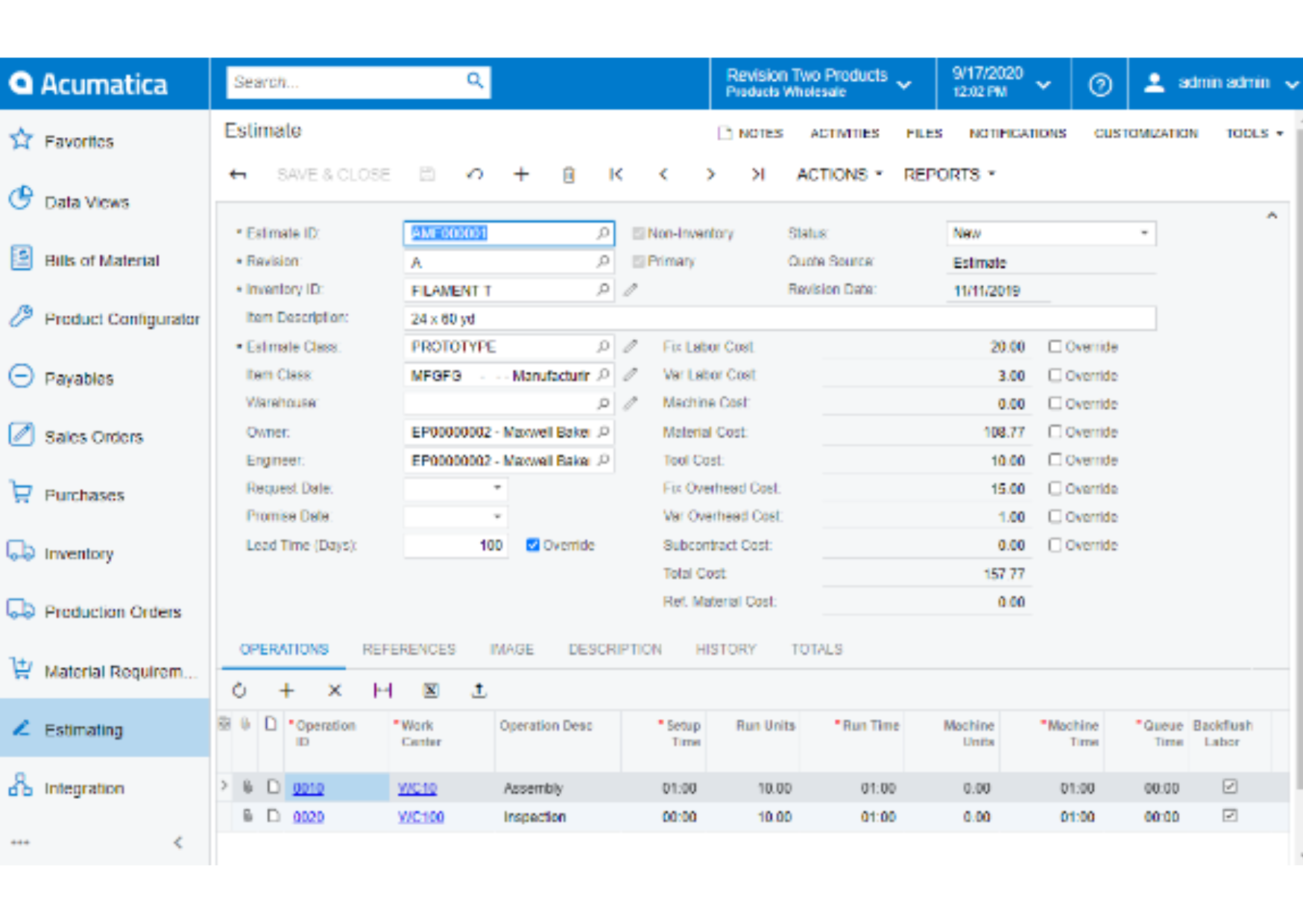

The estimator defines product quantities, component operations, and required tooling costs. Adjust fixed and variable costs, including labour, machine, material, tooling, and overhead. Mark-up estimated cost elements by a percentage or a value. The customer price is rolled up based on the cost elements, markups, and the quantity with one-time costs such as tooling amortized across estimated quantities.

The estimating process provides a total cost by unit with flexibility to adjust costs and prices for both the unit and the estimated total based on the expected quantity to be sold. Send estimate quotes to customers for approval. Quickly convert new items to stock items in inventory for approved quotes. Generic inquiries and reports provide insights into estimate status and details such as conversion rates and estimate accuracy compared with actual production costs.

The estimating module encompasses everything in one location. We were using a ton of Excel spreadsheets…To be able to say, ‘In the future, I can look up this estimate. I can say this is what it cost to produce this part because it’s linked to the production order. That’s huge. Everything in Acumatica links together.

–Jake Rowan, CFO, R&I Industries

Estimate Non-Inventory Items

Estimate items not currently in your inventory. Attach notes, files, and item attributes to the estimate.

Create New Inventory Items

Easily convert non-inventory items to inventory stock or nonstock items. Create inventory items and generate a bill of material from an estimate.

Create Production Orders

Create a production order directly from an estimate.

Sales Integration

Attach an estimate directly to a sales order or an opportunity in Acumatica Customer Management. Create a sales order directly from the estimate.

Flexible Mark-Up

Mark-up material, labour, overhead, and tooling by a percentage or a fixed amount and make final mark-up adjustment to the finished good to improve profits.

Multiple Sites

Easily create estimates from all your company locations.

Optional CAD Connectors

Leverage marketplace CAD connectors to create a bill of material and routing from internally created or customer-provided engineering drawings for new part estimates.

Side Panels

Save time with manufacturing side panels providing direct access to estimate operations, estimates, business accounts, opportunities, sales orders, projects, and project tasks without leaving data entry screens.

Estimate Insights

Leverage role-based dashboards, flexible Generic Inquiries, and reports to monitor estimate status with insights into estimate conversion rates and analysis of estimated versus actual production costs.