Production Management

Production management is challenging without the right tools. Acumatica helps manufacturers to respond with flexibility to adapt to ever-changing schedules, unplanned breakdowns, late supplier deliveries, and other exceptions.

Key business benefits

Related Resources

Take Control Over Production Costs and Schedules with Automation and Real-Time Manufacturing Insights

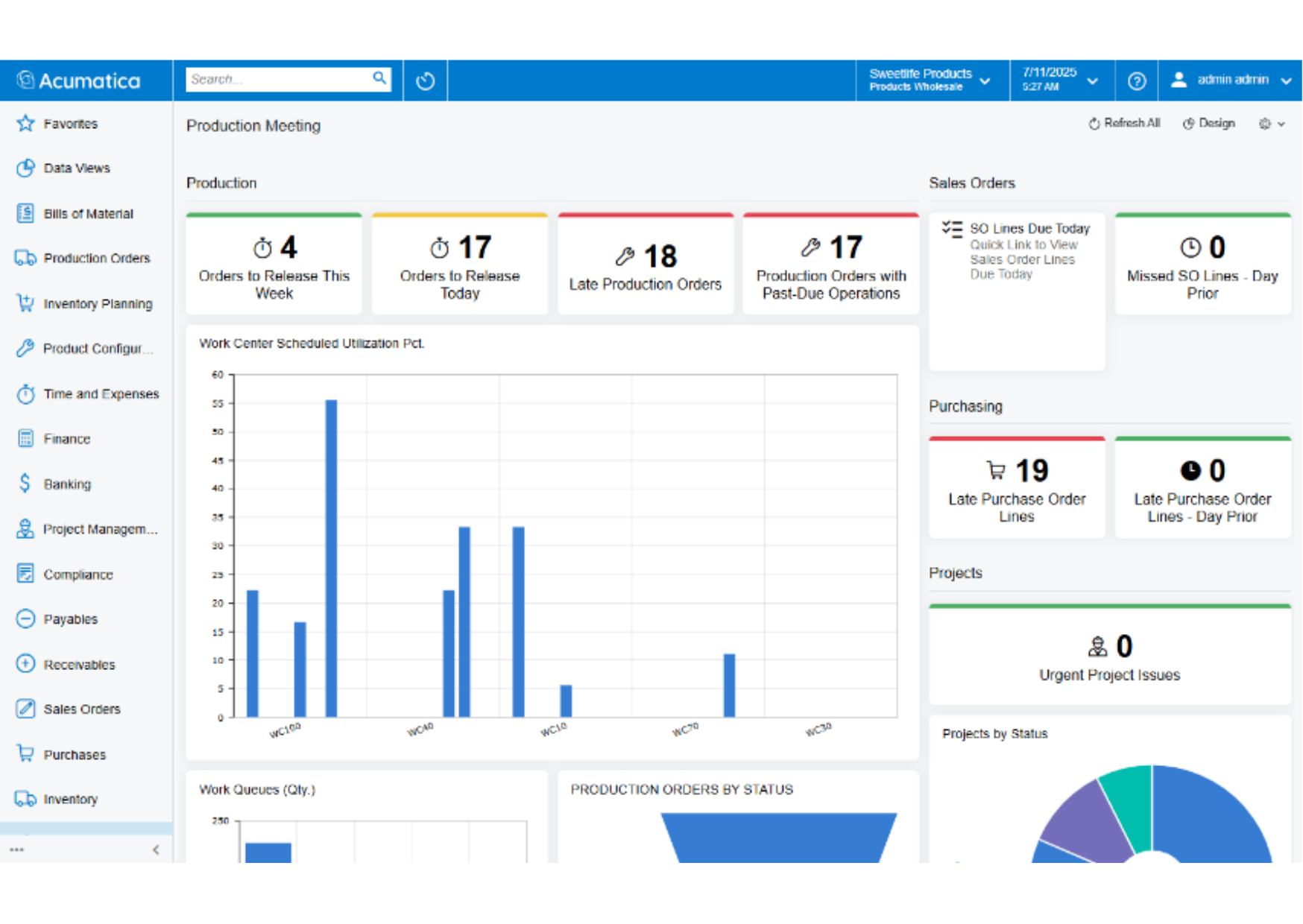

Create production orders from bills of material and routing standards. Release and schedule production orders. Manage outside processes and track materials and labour costs for work in process (WIP) with detailed cost analysis reports, inquiries, and dashboards. Gain valuable insights into production with real-time dashboards, flexible Generic Inquiries, and dozens of personalised reports such as the Production Order Labour Efficiency Report.

PRODUCTION ORDER MANAGEMENT

Production is the heartbeat of every manufacturer. Acumatica Manufacturing Edition streamlines and automates production planning with flexibility to adapt to real-life changes in real-time.

• Create production orders to fulfil customer demand from sales orders or through the material requirements planning (MRP) application.

• Release and schedule production order operations for shop floor employees.

• Capture manufacturing material, labour, machine, tool, overhead, and outside process costs for real-time work in process (WIP) reporting and analysis.

• Monitor production orders from the configurable production dashboard.

• Project-centric manufacturers create production orders directly from tasks in the optional project accounting application.

• Maintain full lot and serial traceability throughout the lifecycle of the item.

Full supply chain visibility will enable us to target the areas where we have issues and tackle them, to ensure we are operating efficiently and driving growth across sales, supply chain, manufacturing and finance.

–Derek Szabo, Managing Director, Devil’s Peak Brewing Company

Critical Materials

View production order shortages. Create purchase and production orders for the parts that are short from a single screen.

Labour Tracking

Capture direct manufacturing labour to production orders by employee. Enter and track non-production time using indirect codes and enter labour transactions directly from the production order maintenance screen.

Backflushing

Eliminate reporting by backflushing labour or material when reporting the production quantity completed, which is useful when a company only wishes to record the production quantity.

Material Tracking

Issue stock and non-stock materials and parts to a production order. Capture lot and serial numbers on controlled items.

Production Performance

Monitor and manage performance with detailed reports, including actual vs. standard/planned costs with labour, material, machine, tool, fixed, and variable overhead details.

Event Audit Trail

Trace all production activities (events) against a production order, including description, date and time, and user ID.

Production Order Changes

Manufacture to prior or alternate bills of material revisions, substitute operations, and materials as desired.

Production Control Points

Streamline data entry with control points to define required milestone operations for production reporting and backflushed operations.

Lot and Serial Tracking

Maintain full lot and serial traceability throughout the lifecycle of the item. Capture lot and serial numbers at purchase receipt, inventory issues, and shop activity transactions.

Barcode Integration

Use barcode data collection to record labour and material transactions and inventory transactions such as issues, receipts, cycle counting, and physical inventory.

Multi-Site

Support multiple sites and have the flexibility to have an alternate BOM/Routing for each site.

Pre-Assign Lot/Serial Numbers

Create and preassign lot and serial numbers for finished goods using configurable number masking. Optionally enforce finished good lot and serial selection when controlled components and raw materials to production to retain one-to-one traceability for multi-quantity production runs. An allocation screen provides after-the-fact matching component lot and serial numbers with finished goods lot and serial numbers.

Outside Processing

Streamline outside processing for vendor shipments and cost transactions related to purchased, subcontracted services such as heat treating, painting, coating, or assembly.

Production Dashboards

Monitor production in real-time with the production manager and production meeting dashboards for insights into work centre utilization, work queues, order status, past due operations, late orders, and work in process (WIP).

Side Panels

Save time with side panels providing direct access to production order details, customers, bill of material, sales orders, customers, projects, and project tasks without leaving data entry screens.

Multiple Base Currencies

Multiple Base Currencies: Manage international manufacturing production costs with multiple base currencies for flexible and accurate financial reporting.

Prevent Over Completions

Prevent production order operation mistakes related to over completion of quantities by production order operation for improved costing and material planning.

Optional Quality Management

Ensure product quality with the optional Quality Management Suite (QMS) for Acumatica. Define and perform quality tests during production with certificates of analysis (COA), nonconformance (NC) tracking, and corrective and preventative action (CAPA) plans.