Warehouse Management

Streamline operations and activities with barcoding and mobile data entry from anywhere in the warehouse.

Key business benefits

Related Resources

Streamline Fulfilment, Reduce Errors, and Increase Warehouse Productivity

Warehouse Management automates operations using barcodes and native mobile apps for faster and more accurate inventory transactions. Know what is happening across your facilities with insights into stocking levels, costs, and warehouse activities.

Acumatica WMS works seamlessly with other applications, including Inventory Management, Sales Orders, Purchase Orders, Service Management, and Production Management with Manufacturing Data Collection.

Mistakes in order fulfilment result in costly returns and lower customer satisfaction. Efficient barcode scanning for lot and serial numbers and pick verification eliminates over-shipments, under-shipments, and incorrect item shipments. Automate routine picking, packing, receiving, put-away, transfers, and physical count activities with customised workflows. Automation eliminates the risk of workers skipping steps, increases productivity, and reduces training costs.

Leverage paperless directed picking with prioritized picking queues for single or multiple orders using wave or batch picking. Complete picking from inventory in a single pass. Flexible location definitions assist warehouse workers who need to quickly locate items in specific aisles, shelves, bins, or other specified locations. Pack items and generate required labels based on package weights or let the system determine the required packaging for specific items.

Connect Acumatica and the embedded WMS system with leading marketplace apps for shipping carrier freight calculations and shipment tracking, coordination with carrier systems, and digital commerce for electronic data interchange (EDI) transactions.

For us, the power of the Acumatica system is in the WMS and shop floor data collection, the inventory management, and the ability to deliver to a customer and to get things right.

–Ben Leinster, CEO, AFF|group

Paperless, Directed Picking

Go green and streamline warehouse operations with prioritised picking queues using paperless, directed picking from mobile devices or ruggedized mobile scanners.

Wave or Batch Picking

Generate wave or batch pick lists based on the best path for each available picker.

Barcoded Pick Lists

Use barcodes to speed up the picking process. Barcodes on pick lists prevent picking items not included in the order.

Packing Definition

Provide adequate package size and packing material to ensure safe transport.

Packing Automation

Packing processes leverage barcodes for accurate item, lot, and serial number data capture. Integrate with digital scales and printers to automatically weigh and print labels and packing slips.

Shipment Creation

Create and prepare shipments inside Acumatica with connections to marketplace apps for small parcel, less-than-truckload (LTL), and other shipping carrier systems for shipment costs, scheduling, and tracking. Acumatica natively supports small parcel shippers and international carriers.

Shipping Labels and Documentation

Automate shipping label generation and required shipping documents such as packing slips required for each shipment.

Customer Notifications

Notify customers when shipments are processed with links to track shipping status via carrier systems. Use business events to alert customers when backordered items are received and ready for shipment.

Stock Turnover

Manage warehouse and retail operations with insights into inventory turnover. Use the inventory turnover ratio inquiry to spot obsolete or slow-moving stock, adjust stock levels for fast-moving items to avoid stock-outs and rush orders, optimise warehouse stock locations, improve replenishment strategies, and benchmark turnover against industry peers.

Physical Inventory

Leverage mobile apps for physical inventory cycle counts and other activities to ensure inventory accuracy.

Carts and Totes

Configure carts for picking and put-away with totes for paperless wave and single shipment picking. Add totes on-the-fly based on quantities required on the pick list.

Stock Movement

WMS supports stock movement within warehouses including warehouse transfers across geographically dispersed locations.

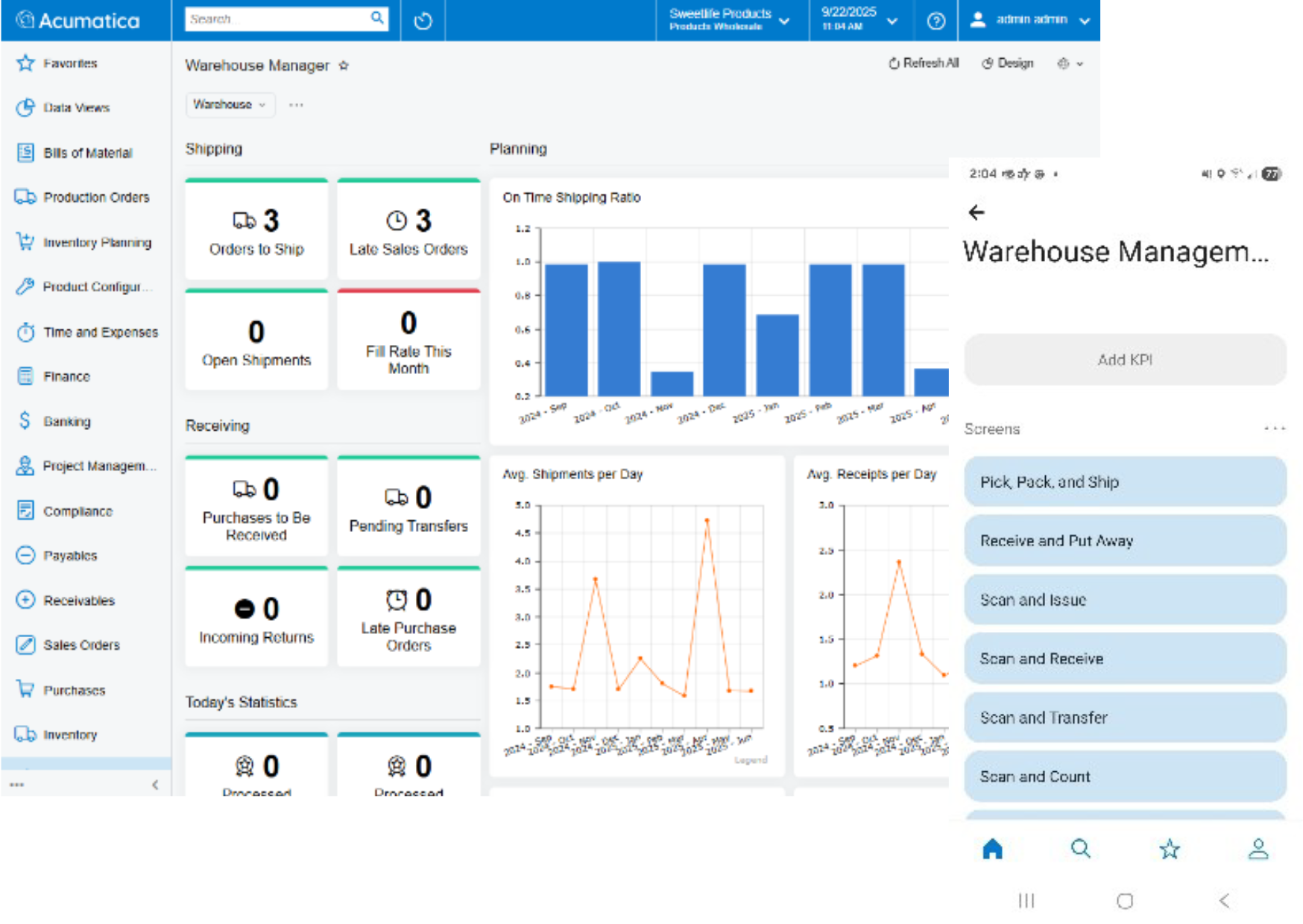

Role-Based Dashboards

Stay on top of your business with role-based dashboards for Purchasing Managers, Shipping Clerks, and Receiving Clerks. Dashboards provide real-time, configurable insights with actionable drilldowns for sales orders, activities, employee productivity, shipments and receipts, on-time shipping ratio, order fill rates, late orders, profitability, return rate, suggested purchase orders, and other key performance indicators.

Side Panels

Distribution side panels provide users with direct access to vendors, items, and order details for sales orders, shipments, purchase orders, receipts, stock and non-stock item maintenance, kit assembly, and template item maintenance.

Optional User-Defined Labels

Create custom labels with the connected Asgard Label application. Create traditional linear or two-dimensional data matrix labels in multiple sizes and orientations containing part numbers, lot and serial details, expiration dates, and more.